Finite Element Analysis

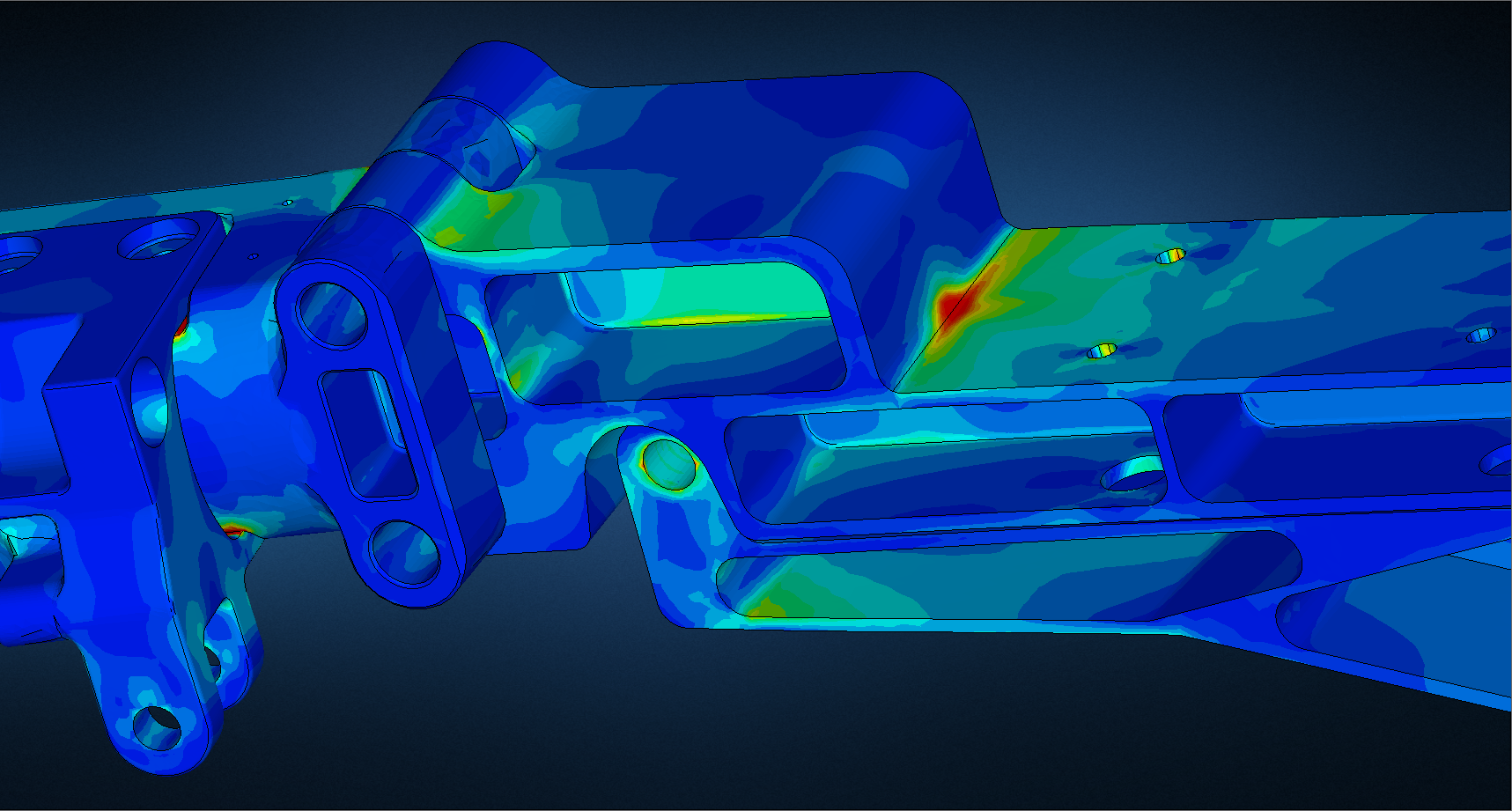

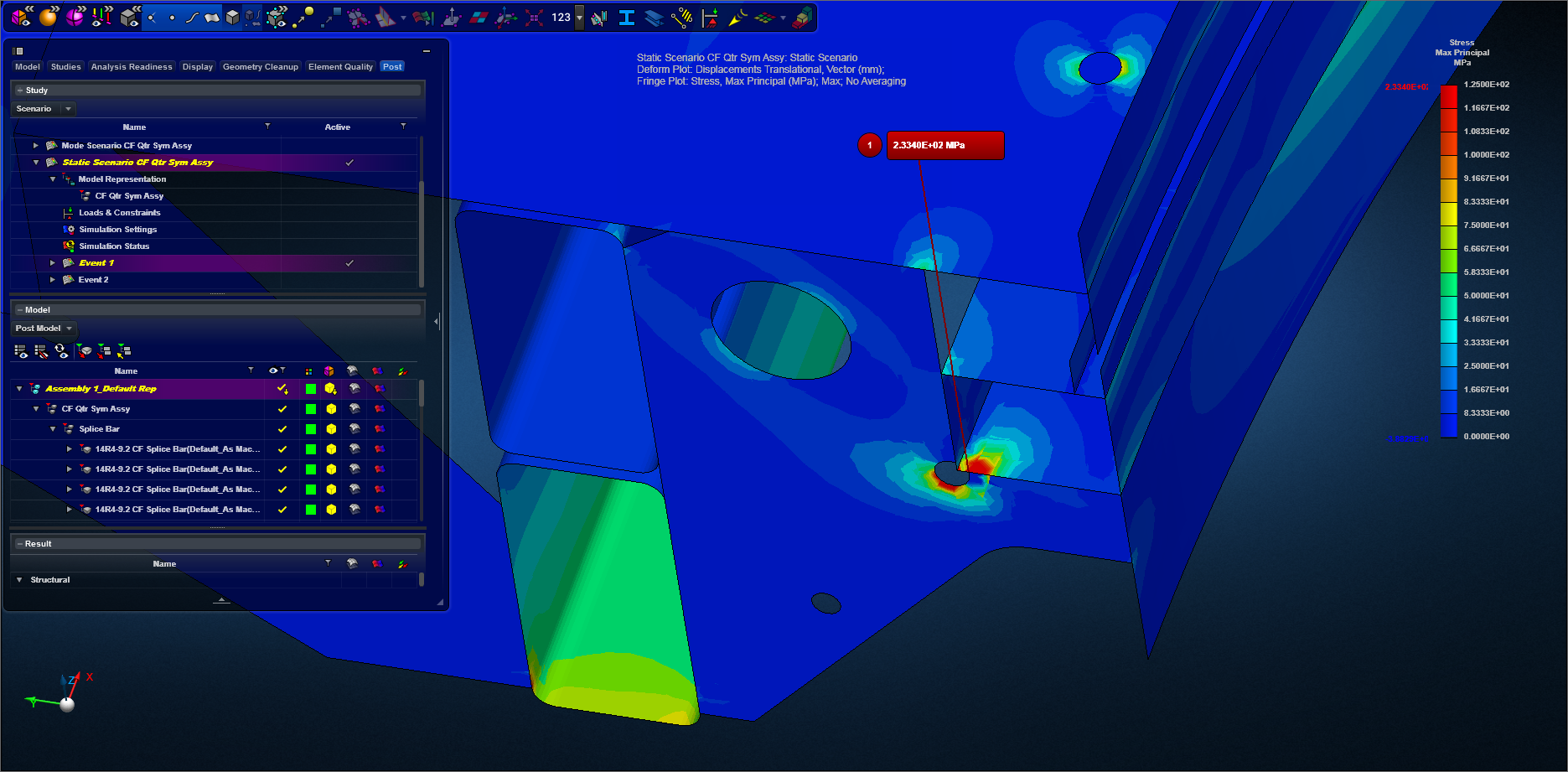

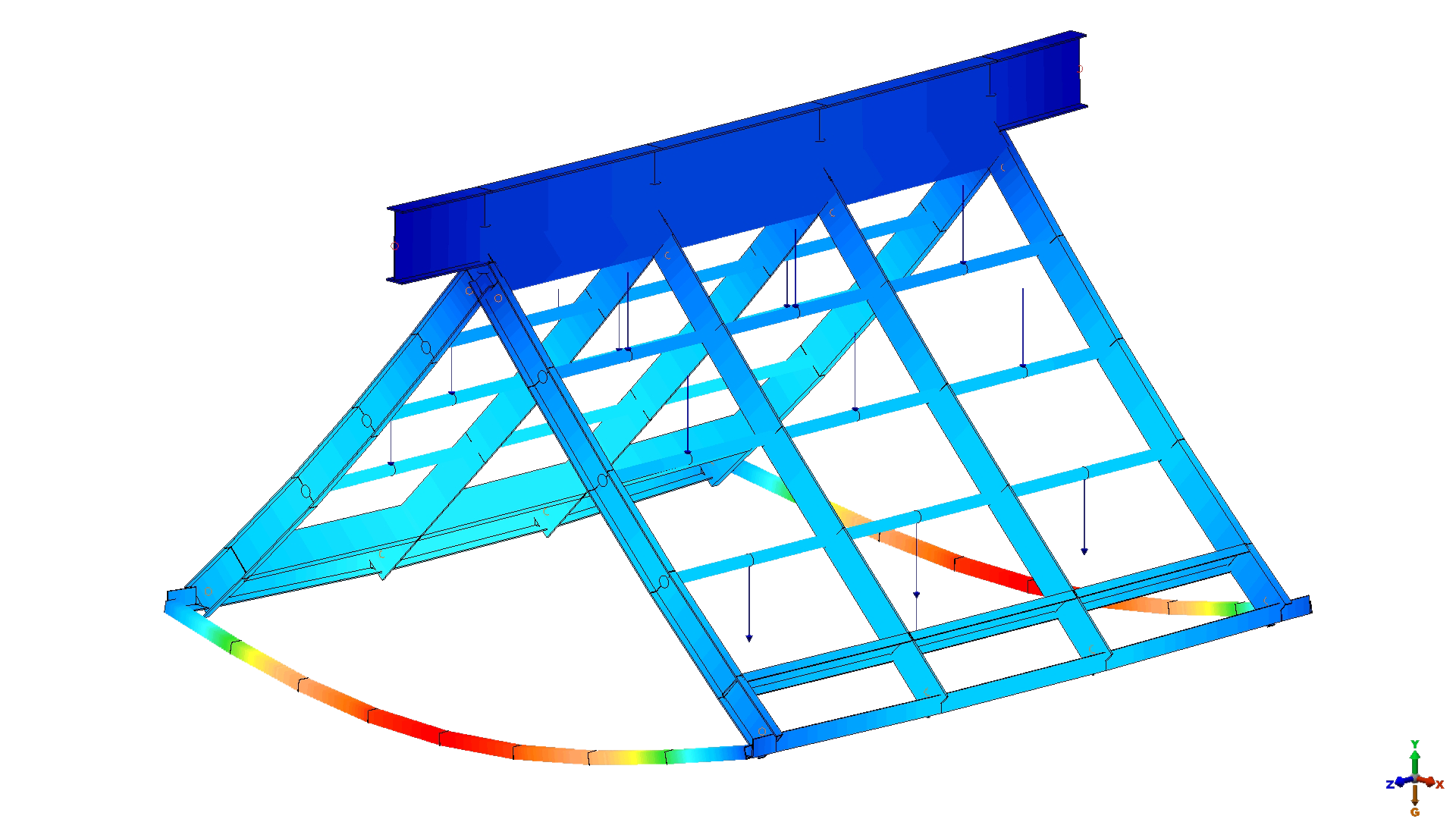

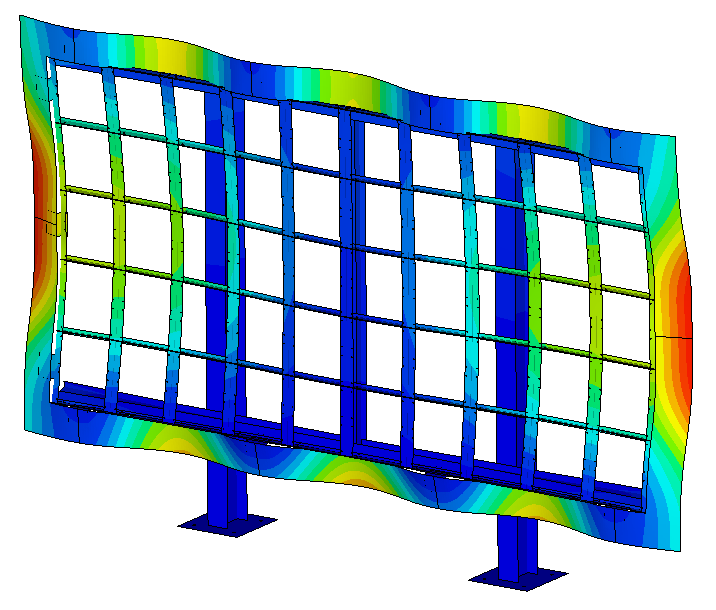

Structures, Assemblies & Components

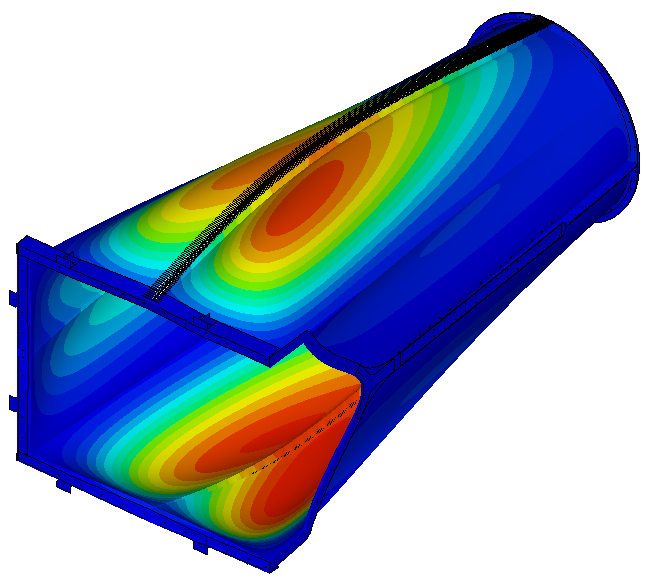

We analyze assemblies, weldments and parts to predict behavior or to ensure integrity or code compliance. Failure modes such as buckling and fatigue as well as non-linear responses such as permanent deformation and large deflections can also be evaluated. Designs can be optimized to reduce material and minimize secondary costs associated with packaging and shipping. Structural simulations are not limited to predictive design studies but can also serve in forensic evaluations.

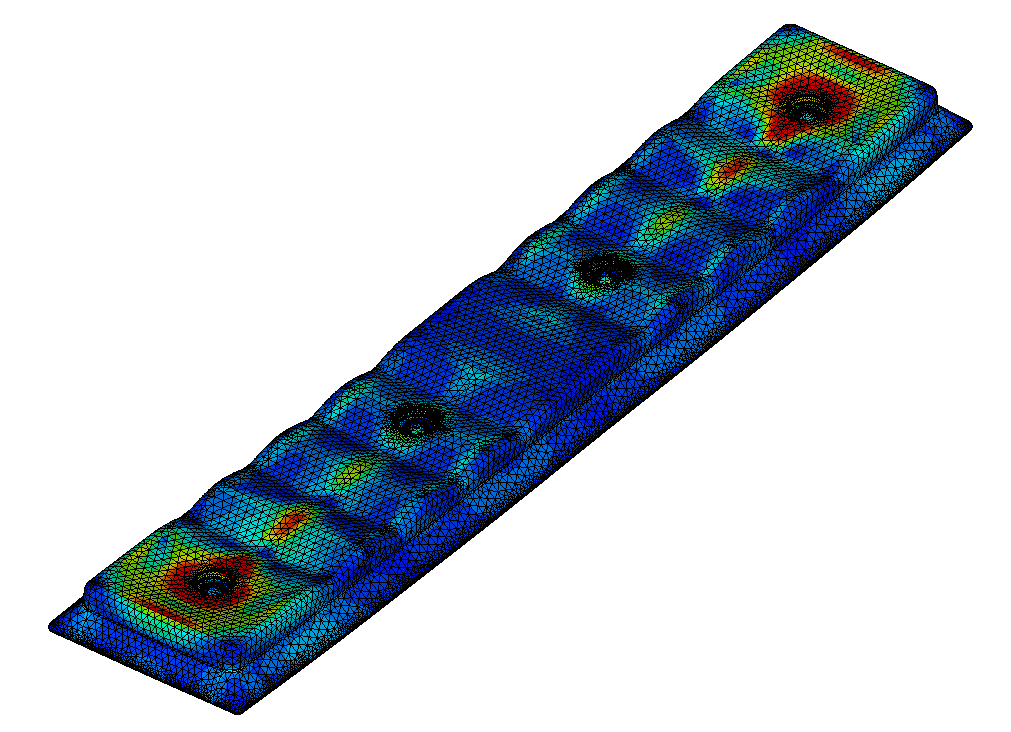

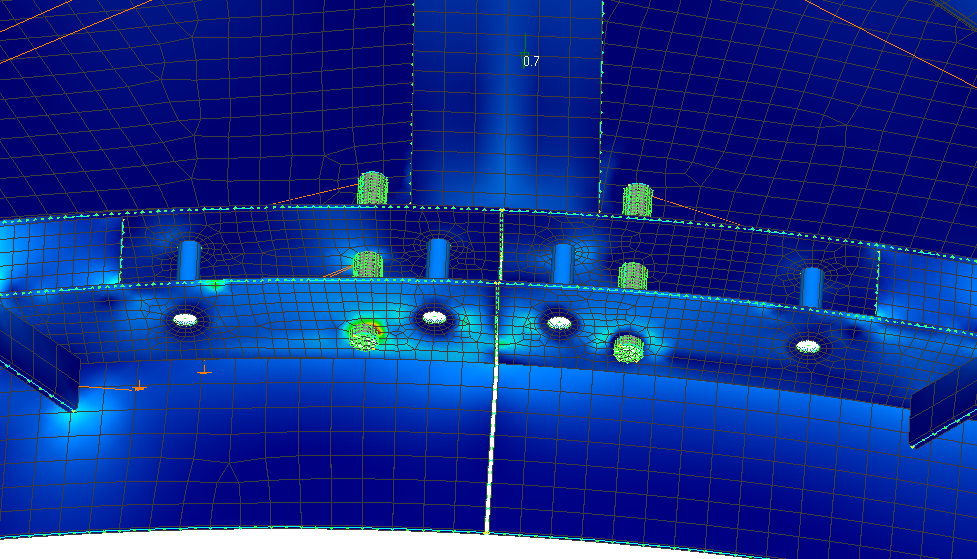

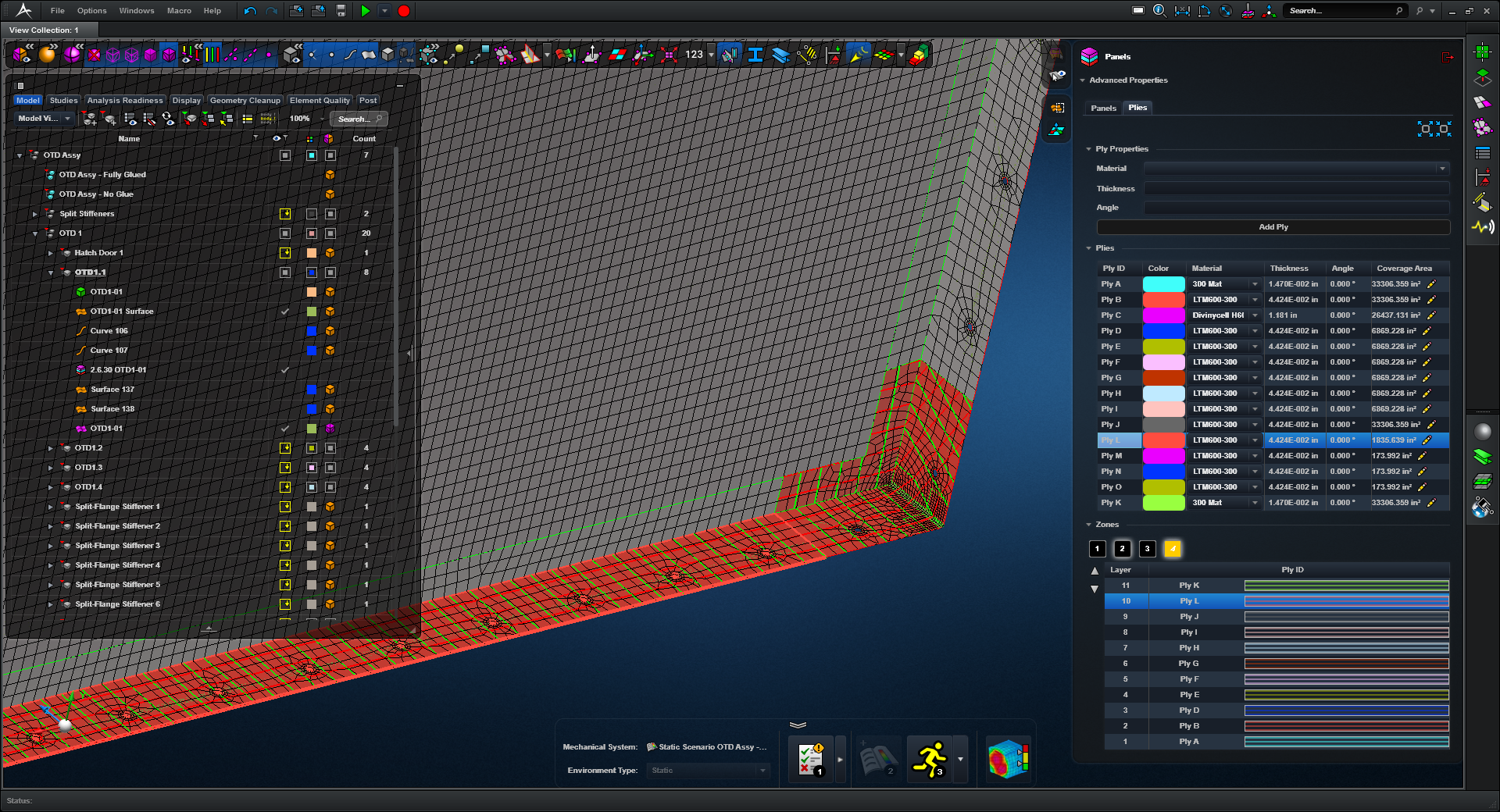

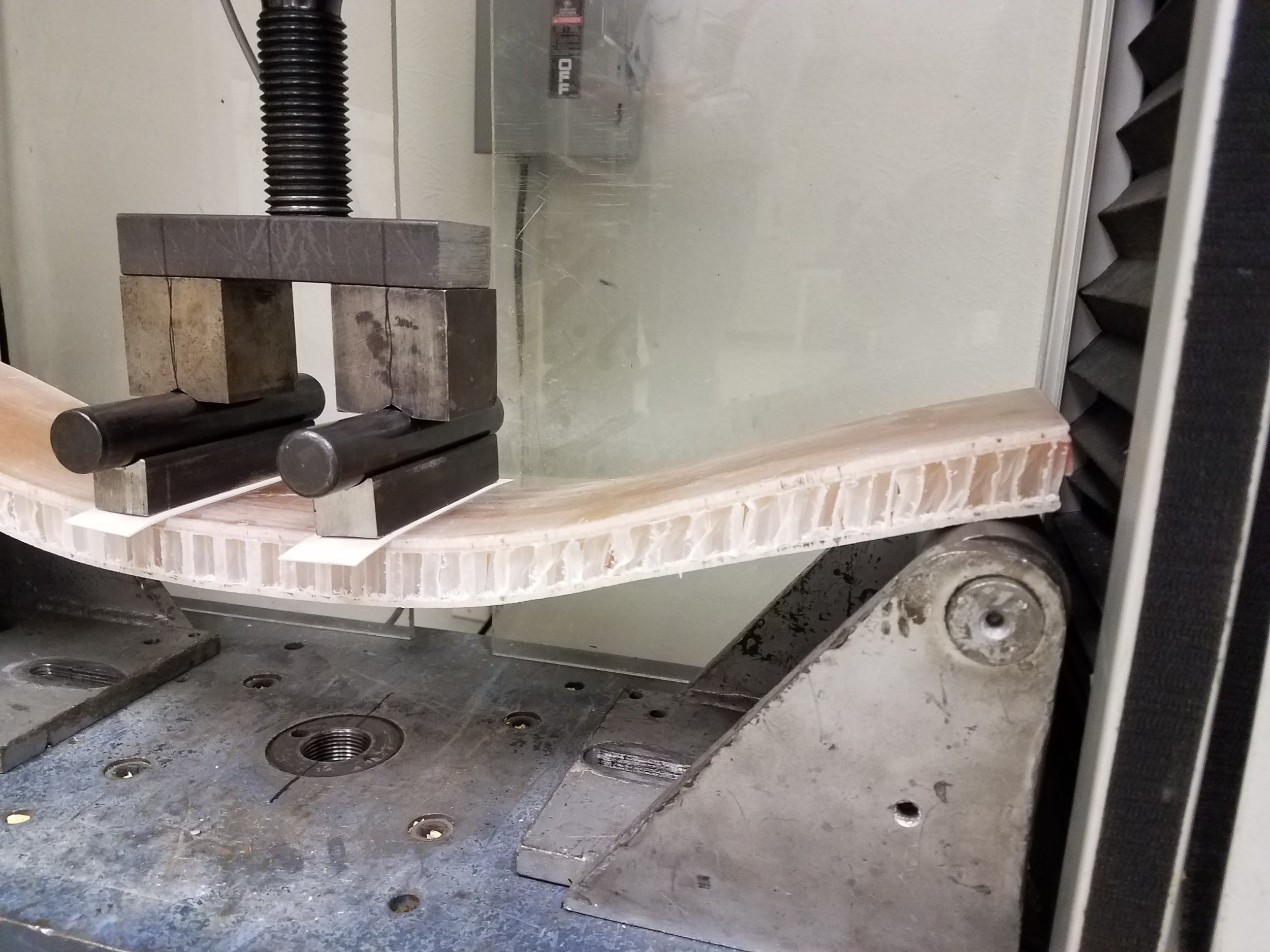

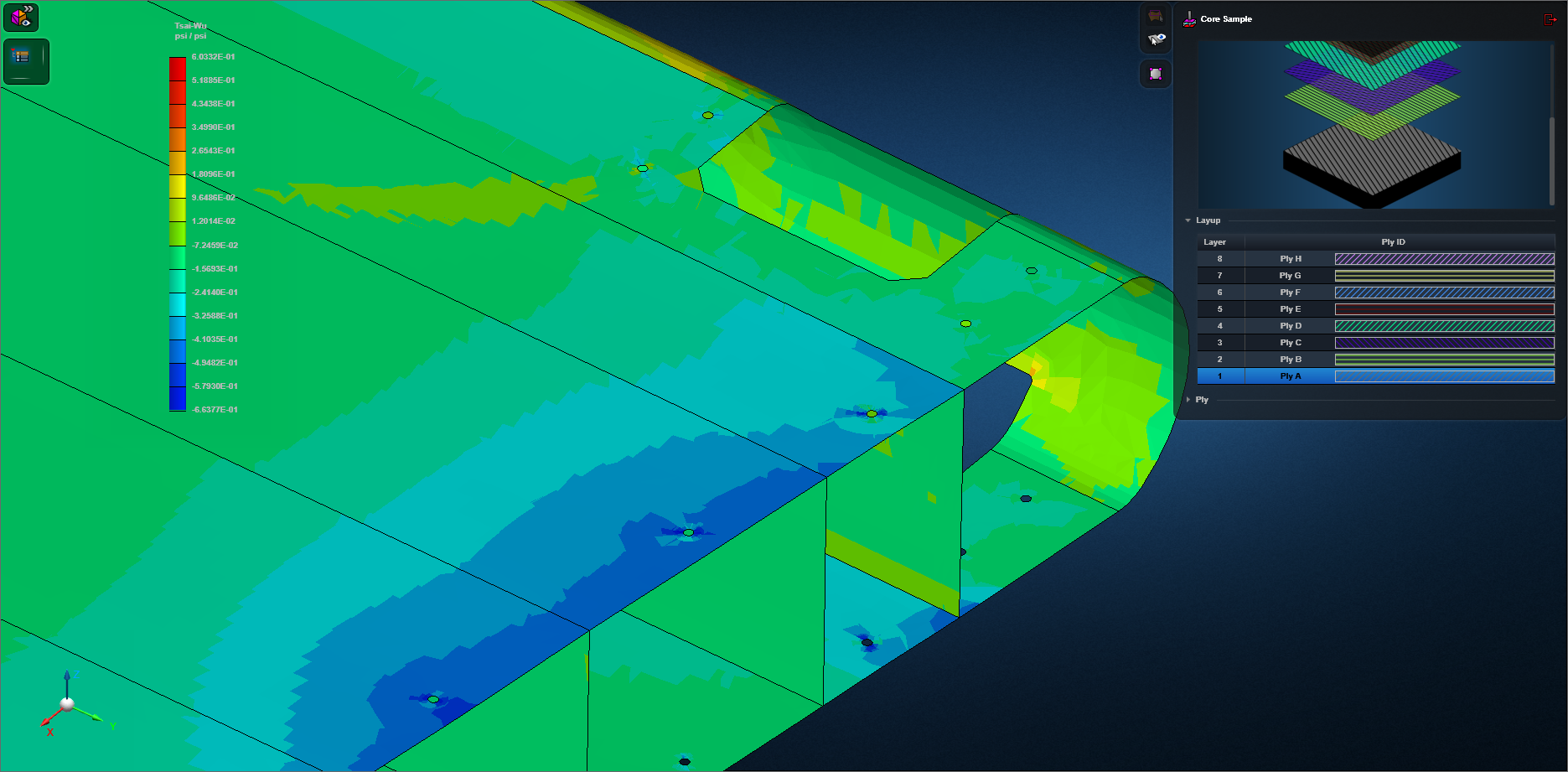

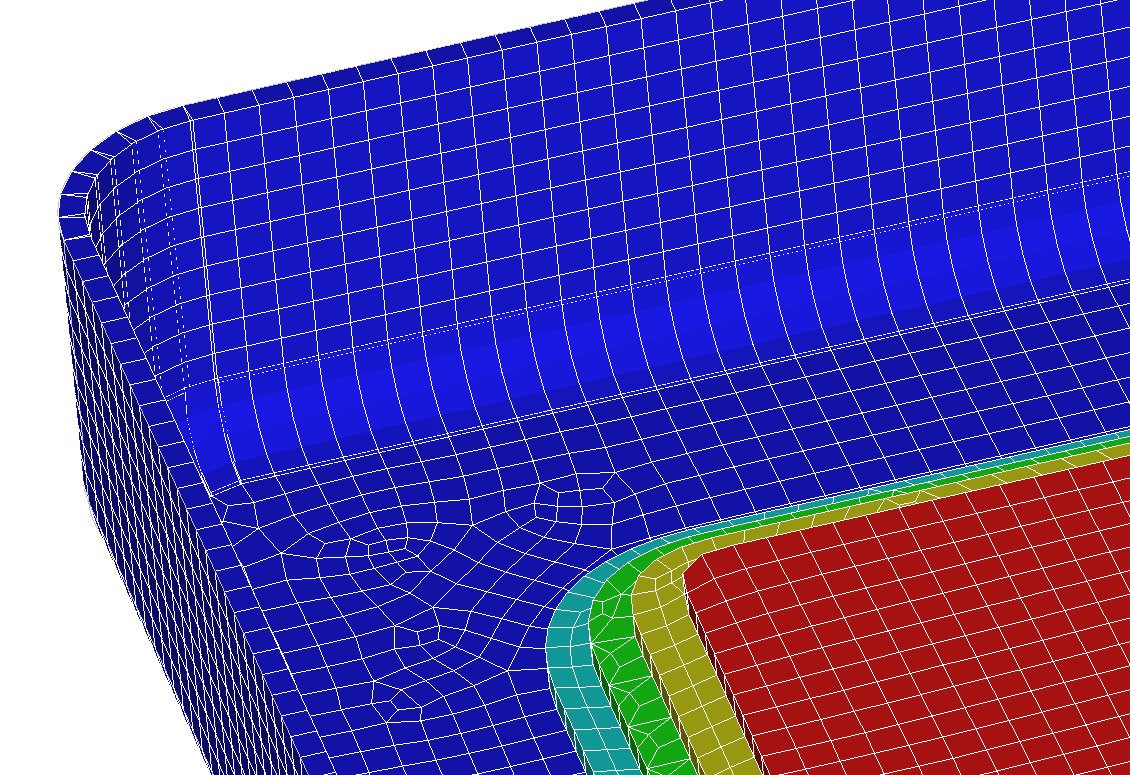

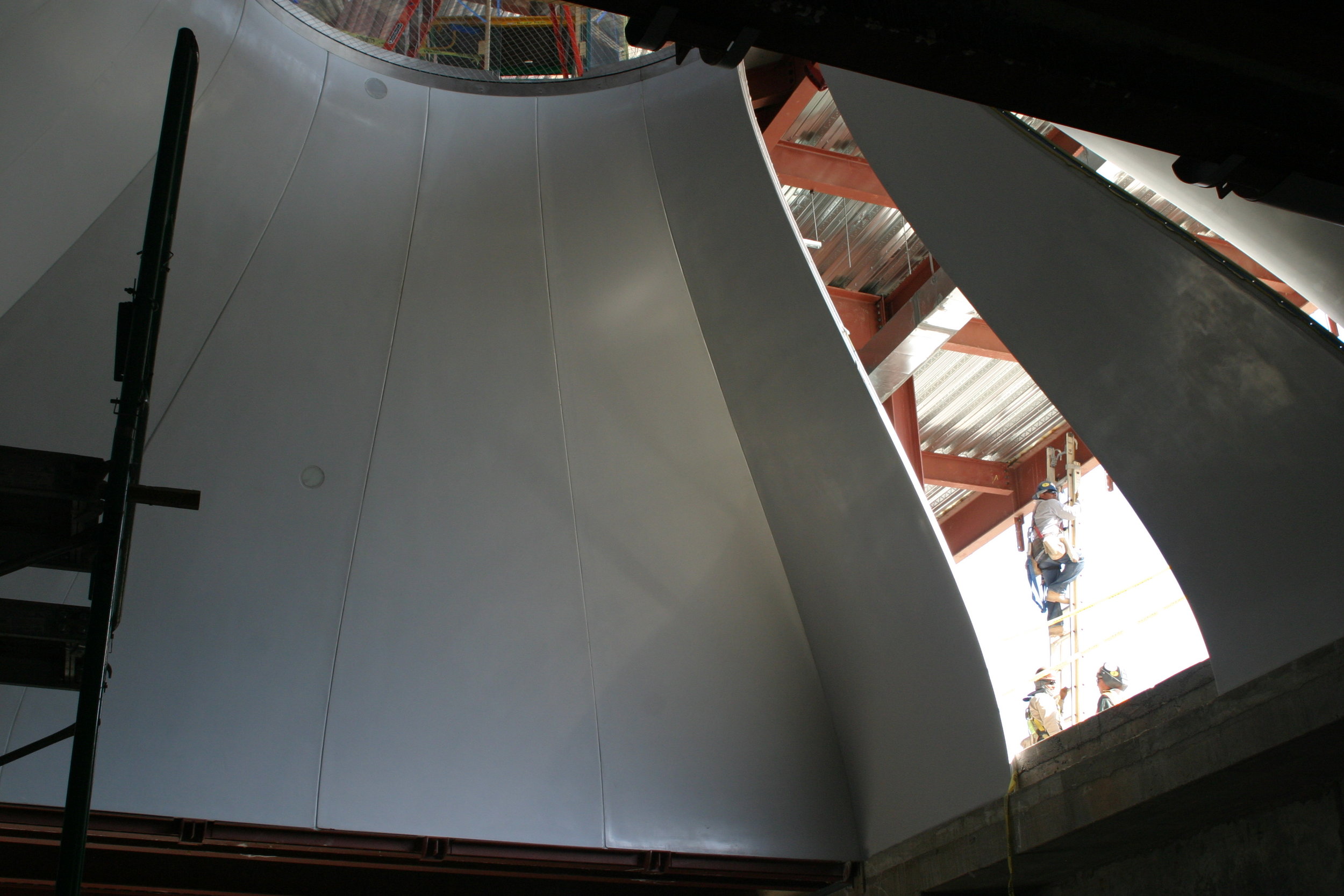

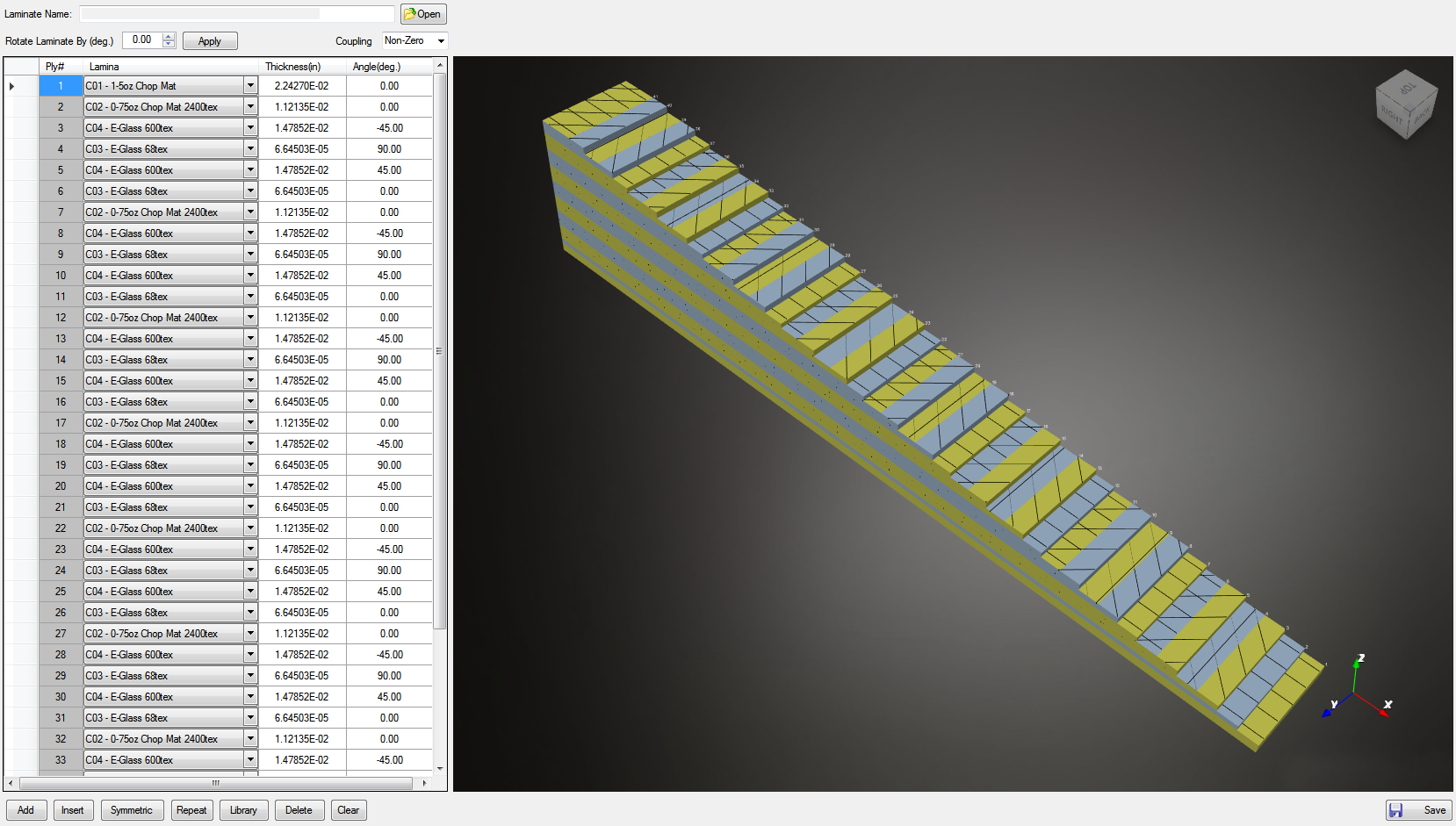

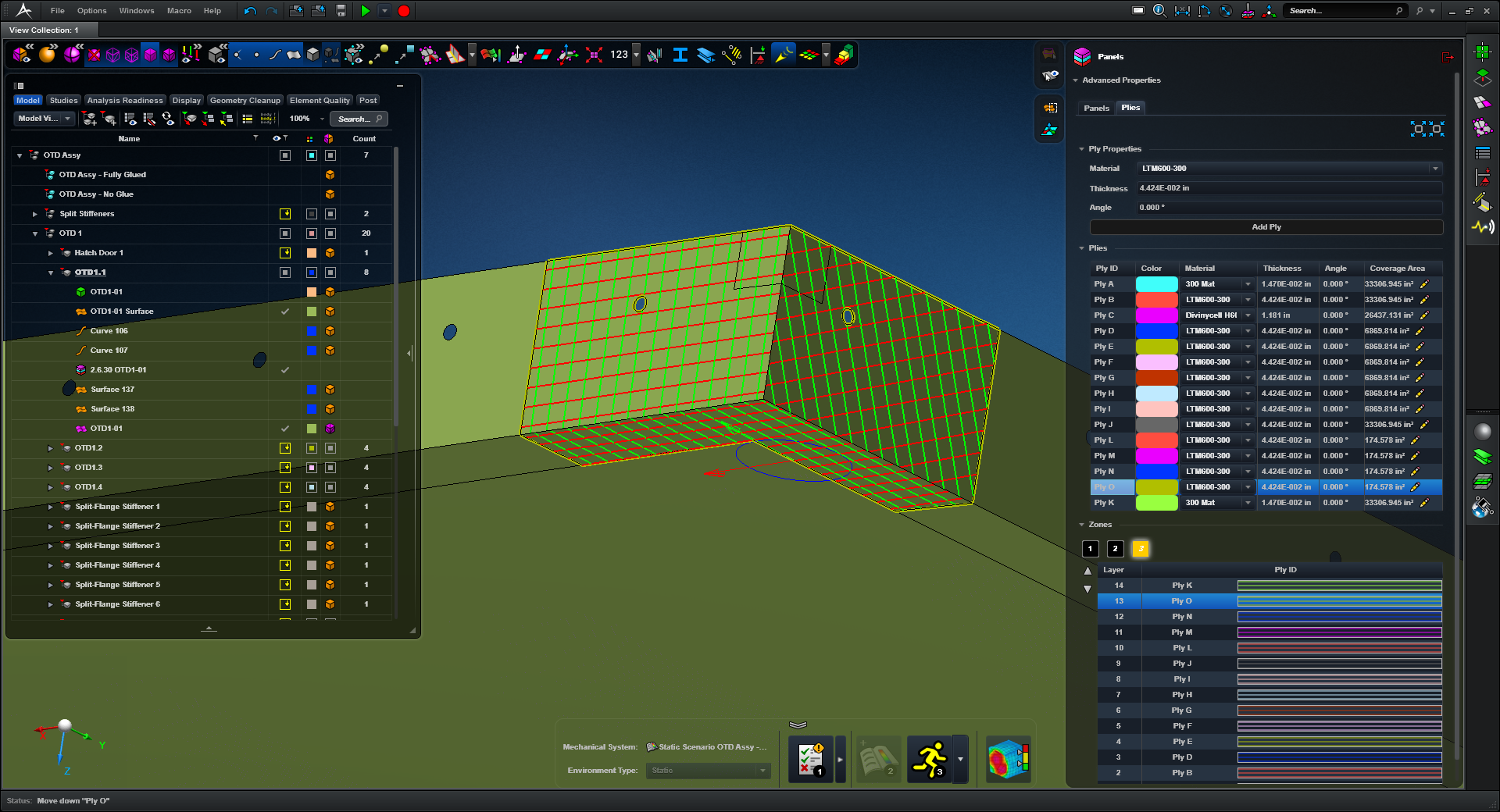

Composites

We simulate the behaviors of layered composites to predict deflections, stresses and failure indices. Design features can be iterated to achieve optimal performance. Failures can be predicted using first-ply failure measures or we can simulate progressive failures that allow for sequential layer failures up to complete breakage. Through our partners in fabrication and testing, we can validate our simulations and generate material properties for other analyses.

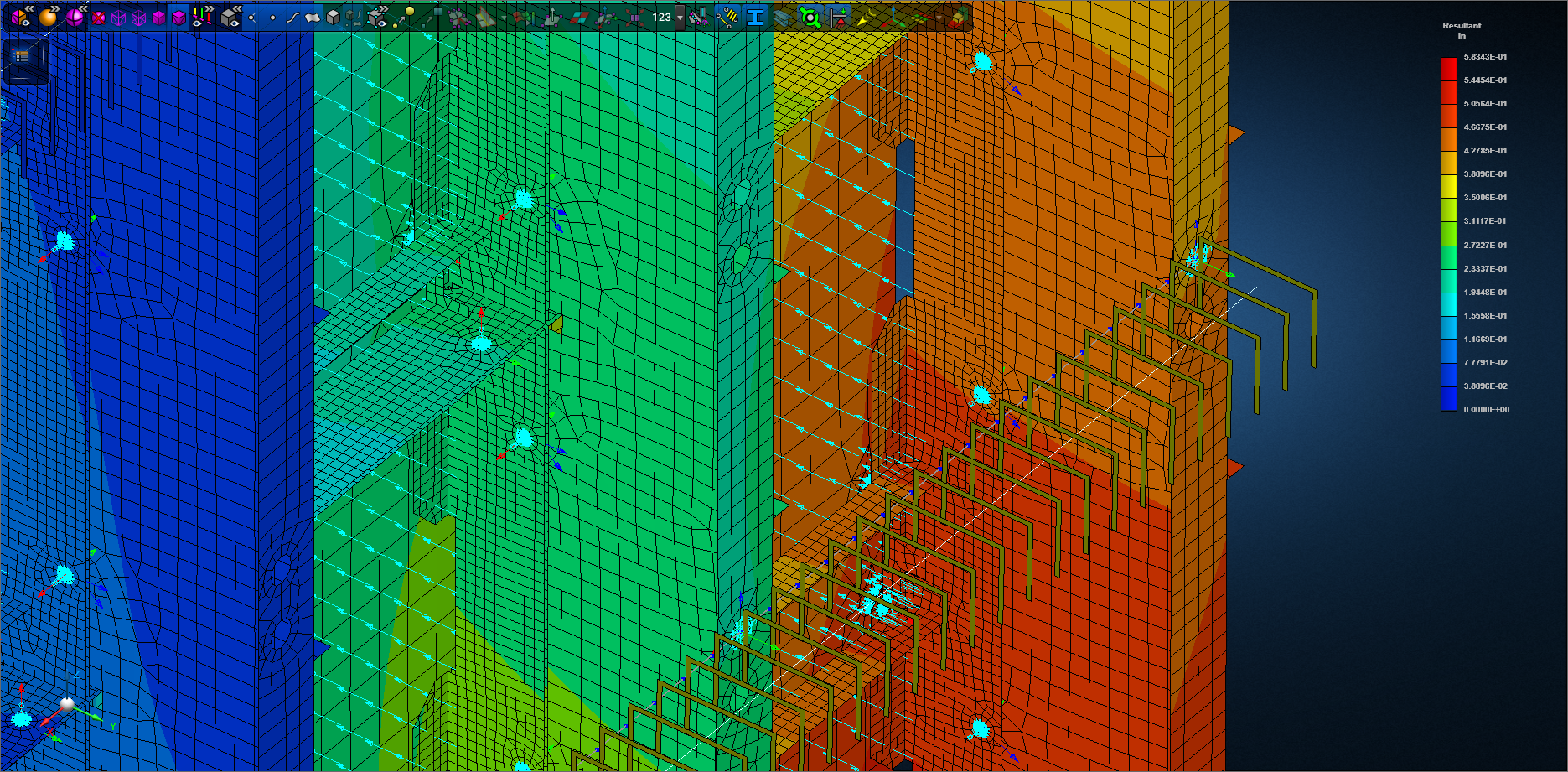

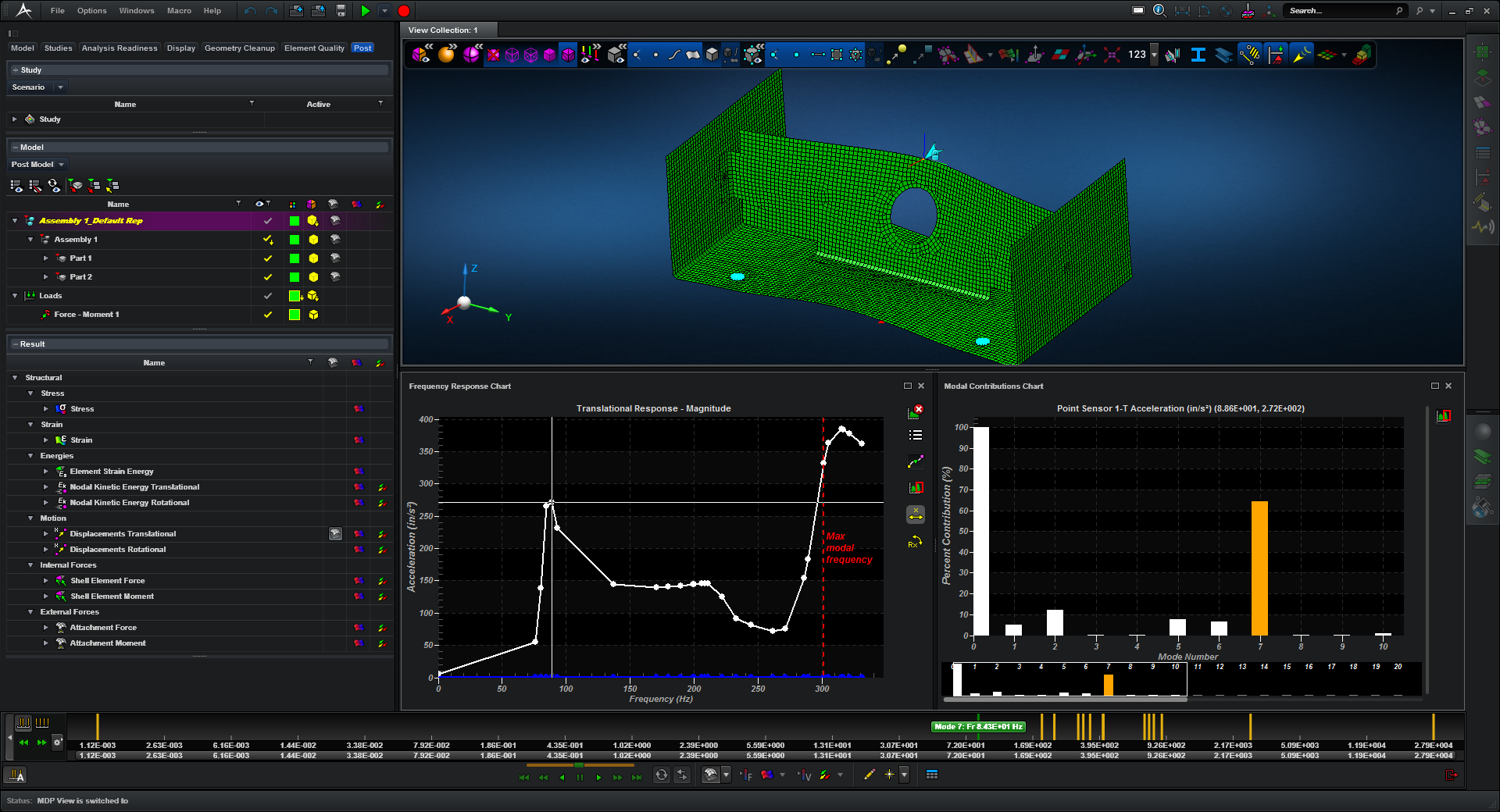

Vibration & Shock

Electronics are often subjected to harsh environmental qualification testing that includes shock and vibration. We can simulate these tests in software up front to help minimize physical testing required. Equipment failure can be predicted and design revisions can be iterated. Common standards include MIL-STD-810, MIL-S-901, SAE J1455, MIL-STD-1540 and GSFC-STD-7000.